Author: Site Editor Publish Time: 2025-10-24 Origin: Site

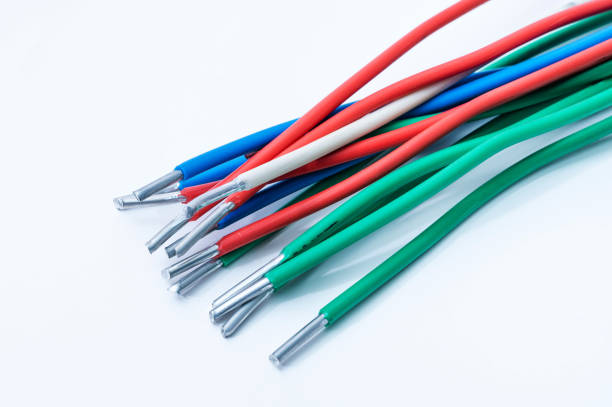

Hook Up Wire, also known as connection wire, serves as a core conductor type for signal transmission and current conduction between components in electronic devices and electrical systems. Widely used across various electrical scenarios from consumer electronics to industrial equipment, its performance and selection directly impact the stability and service life of the entire electrical system. As a fundamental component for electrical connections, the material and structural design of hook up wire must strictly match specific application scenarios. Solid hook up wire and stranded hook up wire, as the two mainstream types, each possess unique structural and performance advantages.

Solid Hook Up Wire features a core structure of a single continuous copper conductor with a fixed and uniform diameter, externally wrapped in insulation for electrical safety.

Superior Connection Stability: The single-conductor structure enables precise positioning during terminal insertion and panel hole passage, minimizing loosening or poor contact.

Significant cost advantage: Compared to stranded wire, solid hook up wire employs a simpler manufacturing process that eliminates the need for additional stranding steps. It also achieves higher raw material utilization. Consequently, solid wire typically offers lower production and procurement costs for equivalent specifications, making it the preferred choice for cost-sensitive projects.

Strong Adaptability for Fixed Applications: In fixed wiring environments requiring minimal movement or bending, solid hook up wires leverage their structural stability to resist minor vibration impacts, reducing the likelihood of circuit failures.

Outstanding current-carrying capacity: With no air gaps within the conductor, solid wires offer a larger effective cross-sectional area for electrical conductivity and lower DC resistance for the same wire diameter. This enables them to handle higher currents while reducing voltage loss during long-distance transmission. They also minimize signal attenuation in high-frequency transmission scenarios, ensuring transmission quality.

Superior Corrosion Resistance: The single-core structure minimizes surface area and crevices where corrosive agents can adhere. Compared to stranded hook up wires, solid wires exhibit reduced susceptibility to corrosion reactions in both indoor and outdoor environments, resulting in extended service life.

Severe Lack of Flexibility: The single-core structure makes bending difficult, rendering solid conductors unsuitable for applications requiring frequent bending or twisting. Forced bending can cause conductor damage or even lead to line breakage.

Weak vibration and fatigue resistance: In environments with continuous vibration or repetitive motion, solid hook up wires are prone to cracking due to metal fatigue. Prolonged use significantly increases the risk of breakage, making them unsuitable for dynamic operating conditions.

Poor adaptability for electronic devices: Due to their high rigidity, solid conductors struggle to fit within the intricate wiring spaces of electronic equipment and digital communication devices, failing to meet the connection demands of precision components.

In printed circuit boards (PCBs) to provide stable circuit connections

Internal wiring within electrical control panels and distribution boxes

Internal wiring in household appliances and industrial fixed equipment, such as refrigerators and air conditioners

Stranded Hook Up Wire consists of multiple fine copper wires twisted or braided through specialized processes to form a flexible conductor structure, also covered by an outer insulation layer.

Exceptional Flexibility: The stranded design enables it to withstand frequent bending, twisting, and movement with ease. It maintains structural integrity in vibrating environments and resists metal fatigue, making it ideal for dynamic applications.

Outstanding Break Resistance: Compared to solid hook up wires, stranded wires maintain electrical continuity even if some strands are damaged. This significantly reduces failure risks from circuit breaks and enhances system reliability.

Strong Adaptability in Confined Spaces: Superior bending performance allows flexible routing around internal equipment obstacles, enabling easy passage through tight wiring spaces in precision electronics and simplifying installation processes.

High Heat Dissipation Efficiency: Natural air gaps between conductors provide pathways for heat dissipation, effectively reducing thermal buildup during current transmission and preventing insulation degradation due to overheating.

Complex Connection Processing: Due to the multi-strand composition, copper wires may loosen or separate during terminal insertion. Additional measures like sleeving or crimping terminals are often required, increasing connection complexity and costs.

Relatively higher cost: Manufacturing stranded wire requires additional twisting processes for fine copper strands, extending production cycles and increasing raw material consumption and processing costs.

Limited current-carrying capacity: Air gaps between conductors reduce the effective cross-sectional area for electrical conductivity. This results in higher DC resistance for stranded wire compared to solid wire of the same diameter, leading to relatively lower current-carrying capability.

Higher corrosion risk: The gaps formed by the stranded structure readily trap moisture, dust, and other corrosive agents, making them more susceptible to corrosion in humid or outdoor environments.

Internal wiring for robots and automated equipment, accommodating frequent and complex device movements;

Connectors for portable instruments, such as handheld testing devices and mobile medical equipment;

Audio cables and speaker connections, leveraging flexibility and transmission stability to ensure sound quality;

Wiring systems in open office environments, meeting flexible demands for frequent spatial reconfiguration;

Internal wiring in vehicles, vessels, and other transportation equipment, adapting to dynamic conditions involving jolts and vibrations.

The dynamic attributes of the application environment are the core basis for selection. For stationary scenarios such as building wall wiring, fixed internal equipment connections, or outdoor direct burial projects, solid hook up wires offer superior stability and cost advantages.

For applications involving frequent movement, vibration, or bending—such as robotic joint wiring, portable device circuits, or reconfigurable cabling in open-plan offices—the stranded hook up wires meet the requirements.

For long-distance cabling (e.g., horizontal links exceeding 10 meters), solid hook up wires are preferred. Their low resistance reduces voltage drop and signal attenuation while meeting industry standards for fixed long-distance links.

For short-distance connections (e.g., inter-device patch cords, internal component jumper wires), stranded wires may be used. Their flexibility facilitates installation, and attenuation/resistance issues over short distances have minimal impact on system performance.

For fixed installations with budget constraints and a focus on long-term stability, solid wire offers a cost-effective solution that balances affordability with system reliability.

In dynamic environments demanding flexibility and fault tolerance, a slightly higher budget for stranded wire is advisable to prevent equipment downtime and increased maintenance costs from wire breakage.

Solid hook-up wire and stranded hook-up wire are not inherently superior or inferior; the core of selection lies in matching specific application scenarios and electrical requirements.

For fixed installations involving long-distance transmission, high current loads, and limited budgets, solid wire is the preferred choice due to its stability, high current-carrying capacity, and cost advantages.

Stranded wire's flexibility and resistance to bending better suit short-distance connections requiring frequent movement, vibration tolerance, and adaptation to confined spaces.

Users are advised to comprehensively evaluate key factors such as the dynamic characteristics of the application environment, wiring length, and current requirements when selecting wire types. Consulting professional wire suppliers like Hongsen Cable when necessary, and developing optimal solutions based on industry standards and project specifics, will ensure the safe, stable, and efficient operation of electrical systems.

PVC vs FEP Hook Up Wire: Which Insulation Material Is Right for Your Project?

Selection and Applications between 20 vs 18 vs 16 Gauge High Temperature Wire

Which One Is Better Solid Hook Up Wire vs Stranded Hook Up Wire?

Which Insulation Material Is Used for High Temperature Wire?

Why PTFE Hook-Up Wire Excels in Chemical Processing and Medical Devices

The Complete Guide to Hook-Up Wire Types: Materials, Ratings, and Applications

Top 5 Benefits of Using FEP Hook-up Wire in Industrial Applications

FEP vs PTFE Hook-up Wire: What’s the Difference and Which One Do You Need?

|Copyright 2002-2019 Hangzhou Hongsen Cable Co., Ltd. All Rights Reserved. Coaxial Cable Manufacturer

Powered by hi-eweb.com | Sitemap | XML